Tower Clock History

Thanks go to Jack Thornton for his research about our Tower Clock, and for looking after the clock on our behalf for many years.

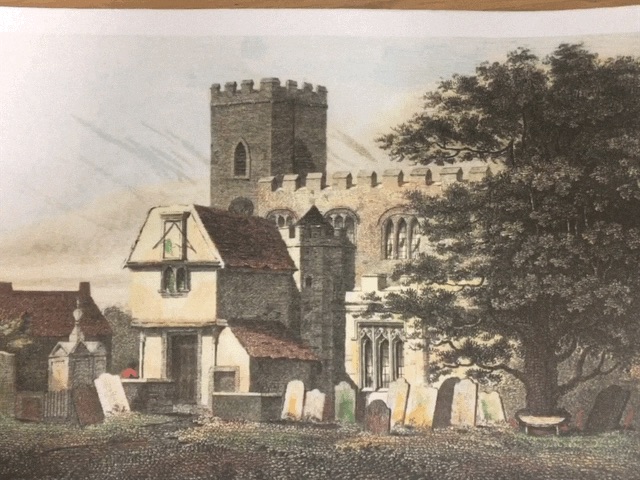

The tower clock was installed on the second floor of the bell tower in December 1910, in a large wooden cupboard.

The makers, F.W. Benson of Ludgate Hill (see Note 1 below), were clearly proud of this fine example of Victorian engineering as the huge iron frame carries a brass plate with the inscription ‘Clockmaker to the Queen and Prince of Wales.’ This referred to Queen Victoria and Prince Edward, so the mechanism appears to have been made before 1901.

The wood rod pendulum beats 1.5 seconds and is coupled to a ‘dead beat’ escapement mounted in the flatbed frame. The pendulum weighs 100lb (47kg) and is about 8ft (2.5m) long. It passes down through a slot in the floorboards to the first floor, where fine adjustments of timekeeping rate can be made by adding or removing small weights, in the form of steel washers hung on a hook attached to the rod. For example, if the clock is losing 7 seconds a week, the addition of an 8-gram washer will correct the rate.

There is always a need for slight correction at least twice a year due to the change of temperature in the tower between summer and winter.

The escapement is coupled by bevel gears to a long vertical shaft, which reaches to the top of the tower, where a gearbox transfers the drive directly to the minute hands of the two dials.

The tower clock was installed on the second floor of the bell tower in December 1910, in a large wooden cupboard.

The makers, F.W. Benson of Ludgate Hill (see Note 1 below), were clearly proud of this fine example of Victorian engineering as the huge iron frame carries a brass plate with the inscription ‘Clockmaker to the Queen and Prince of Wales.’ This referred to Queen Victoria and Prince Edward, so the mechanism appears to have been made before 1901.

The wood rod pendulum beats 1.5 seconds and is coupled to a ‘dead beat’ escapement mounted in the flatbed frame. The pendulum weighs 100lb (47kg) and is about 8ft (2.5m) long. It passes down through a slot in the floorboards to the first floor, where fine adjustments of timekeeping rate can be made by adding or removing small weights, in the form of steel washers hung on a hook attached to the rod. For example, if the clock is losing 7 seconds a week, the addition of an 8-gram washer will correct the rate.

There is always a need for slight correction at least twice a year due to the change of temperature in the tower between summer and winter.

The escapement is coupled by bevel gears to a long vertical shaft, which reaches to the top of the tower, where a gearbox transfers the drive directly to the minute hands of the two dials.

Notes:

Note 1: In the 1850’s J W Benson opened premises at Ludgate Hill, with a steam powered clock factory nearby. He died in 1878, leaving two sons, Alfred and Arthur to continue the business. In 1879 the company was awarded a Royal Warrant by Queen Victoria, followed by those of Edward Prince of Wales and the Kings of Denmark and Siam. Manufacturing ended when the factory was bombed in WW2.

Note 2: In late Victorian times chemists were working to develop oils suitable for lubricating steam engines, initially using combinations of petroleum, animal and vegetable fats. Lubricating oils in use at that time included almond oil, coconut oil, fish head oil, lard oil, olive oil, rapeseed oil and whale oil.